Our many Departments span deep across the entire production process. From initial concept and design, to installation and testing, we cover all phases of your automation project with proven expertise, all under one roof! Below are just a few of Brooks Machine’s highlighted capabilities:

Our Capabilities

- Mechanical & Electrical Engineering

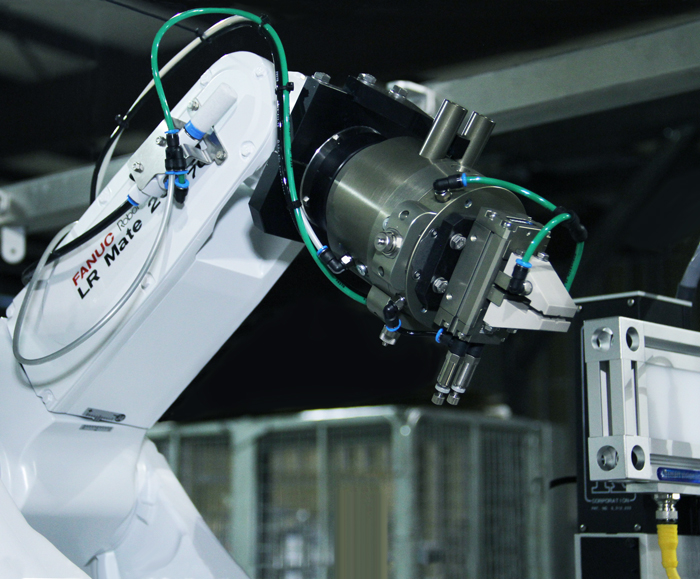

Our experienced Electrical Engineers have extreme versatility in all types of programmable controllers and can design controls for custom automated systems to meet your needs. Our in-house Controls team builds electrical panels and handles the pneumatics for all projects. We also design systems that utilize advanced Robotics and Servo/Pneumatic Motion Control, with integration certifications from today’s leading robotic manufacturers.

- Fabrication

In our modern 52,000 sq ft facility, we house a fully operational machine shop capable of handling all facets of our Fabrication processes for new parts. We custom-make all machine frames, brackets and supports in-house as well as bend all sheet metal for any size installation. Our expert Fabrication team of welders, machinists and engineers is always eager for the next challenge!

- Machining

As a subset of our advanced Fabrication capabilities, it is important to note our stand-alone Machining services, consisting of state-of-the-art CNC Milling Machines, CNC Lathes, Manual Milling Machines and Lathes, CNC Gantry Mill and a 10′ OMAX WaterJet. With this assortment of milling tools, our seasoned machinists will deliver the most optimal solution to build your product right.

- Assembly

Our complete in-house assembly capabilities are made possible by our well-equipped 52,000 sq ft facility and abundance of in-house solutions for fabricating custom parts. Our many certified integration partnerships with innovators such as FANUC grant us our full in-house capabilities to assemble our advanced automation lines from design to delivery.

- Documentation

At Brooks Machine, we pride ourselves in providing added value to the automation process. We use the latest in web 4.0 and information gathering technologies to document each step of your automation line and maintain this testing data for your future reference. As technology gets smarter, so should your data from your new custom automation line; helping you predict disruptions before they happen.

- Installation

Just as hands-on as our in-house assembly team, our same group will install your new automation project on-site, on-point and on-time. We pride ourselves in every step, from design to delivery, to ultimately be able to streamline your process as quickly and efficiently as possible!

- Machine Vision

Keeping pace with the rapidly growing field of Machine Vision, Brooks Machine has designed and built a multitude of systems that apply this smart and flexible, technology. From guidance fixtures to complete inspection machines, we have implemented both single and multi-sided product vision techniques using multiple cameras and back lighting techniques. The result: smarter, leaner processes for our clients.

- Robotics

Brooks Machine has firmly stood on the cutting edge of the Robotics industry by both producing and commissioning countless robotic systems over the years. From SCARA (Selective Compliance Assembly Robot Arm) robots to giant Gantry robotic systems, we find the perfect robotic solution for threading a needle or hauling thousands of pounds of material.

Our six-axis capabilities leave virtually no limits to our material handling and our hi-speed pick and place solutions are at the forefront of today’s industry capabilities. Brooks is proud to be a FANUC Authorized Systems Integrator, utilizing an unbeatable arsenal of robotic solutions completely assembled in-house.